Self-repairing

ceramic for aircraft engines

"Japanese analysts claim to have built up a fired material that self-repairs splits in only one moment and could definitely change fabricating strategies for the transportation business"

Full Story:

The

group from the National Institute for Materials Science (NIMS) and Yokohama

National University, Japan said the material could be utilized as a part of

plane motors to keep them working regardless of whether they are harmed in

crashes with airborne items.

Toshio

Osada, a senior specialist at the NIMS, stated: "When the plane motor

endures a break amid a flight, the earthenware material will empower the

airplane to repair the harm independent from anyone else before arriving

without halting the motor."

Wataru

Nakao, a designing teacher at the college, said the material "can be

utilized for a wide assortment of items," and the group is arranging

concentrates to market it.

Clay

influenced motors to have been viewed as a conceivable method to enhance

fuel-proficiency as it is lighter and more warmth safe than nickel and

titanium, however was considered excessively delicate for use in air ship

motors.

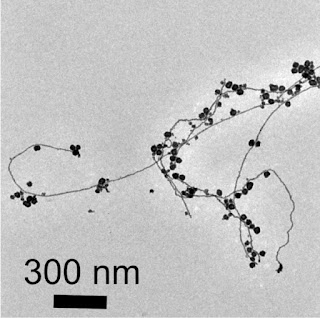

To take

care of the issue, the specialists added silicon carbide to an earthenware

material made of aluminum oxide. At the point when the earthenware broke at

high temperatures, the silicon carbide was presented to air and transformed into

silicon dioxide that filled in the split and repaired the harm.

The

self-recuperating process at first required around 1000 hours to finish,

however the NIMS specialists have now diminished the opportunity to one moment

under temperatures of 1000°C by including a small measure of manganese oxide

which they said advances the wonder.

The

researchers said they are chipping away at upgrades with the goal that the

material can repair harm at bring down temperatures, making it feasible for use

in the undercarriages of Shinkansen shot trains.

Comments

Post a Comment