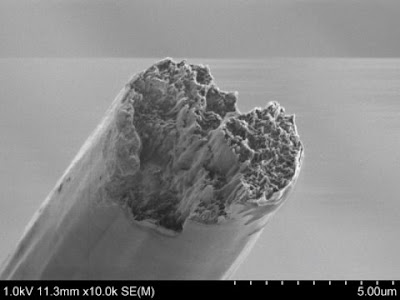

World's Strongest bio-material outperforms steel and spider silk Novel method transfers superior nanoscale mechanics to macroscopic fibers Full Story: The ultrastrong material is made of cellulose nanofibres (CNF), the fundamental building squares of wood and other vegetation. Utilizing a novel creation strategy, the analysts have effectively exchanged the exceptional mechanical properties of these nanofibres to a naturally visible, lightweight material that could be utilized as an eco-accommodating option for plastic in planes, autos, furniture and different items. "Our new material even has potential for biomedicine since cellulose isn't dismissed by your body," clarifies Söderberg. The researchers began with economically accessible cellulose nanofibres that are only 2 to 5 nanometres in distance across and up to 700 nanometres in length. A nanometre (nm) is a millionth of a millimeter. The nanofibres were suspended in water and encouraged into