Improving 3-D printing of plastic parts:

3-D printed parts. Yet, as excitement for 3-D

printing keeps on developing and grow crosswise over business sectors, the

articles printed by the procedure can have shortcomings. Presently, one gathering

reports in ACS Applied Materials and Interfaces that utilizing a

straightforward alteration to the make of the beginning materials enhances the

durability of these printable plastics.

Full Story:

As the 3-D printing market

extends as well as turns out to be more reasonable, it is discovering

applications in a wide range of zones. Be that as it may, this adaptability is

restricted by the quality and solidness of the printed parts. A large portion

of these items are imprinted in layers, which intrinsically brings about

powerless spots where the layers meet. In this way, 3-D printed objects are not

as solid as those made with current strategies in which plastics are infused

into molds. To make more grounded 3-D printed parts, Heads and associates needed

to investigate whether the beginning materials could be changed to

self-strengthen the printed parts.

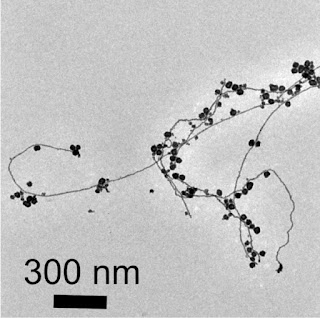

The scientists influenced an

organized, center to shell polymer fiber in which a polycarbonate center goes

about as a solid skeleton to help and fortify the 3-D printed shape. An olefin

ionomer shell around the polycarbonate center enhances and fortifies the

association between the printed layers. Amid testing, printed parts with the

fibers could withstand impacts without breaking, not at all like parts made

without them. The new fibers convey 3-D printed parts nearer to the quality of

parts made by current techniques.

Comments

Post a Comment