World's Strongest bio-material outperforms steel and spider silk

Novel method transfers superior nanoscale mechanics to macroscopic fibers

Full Story:

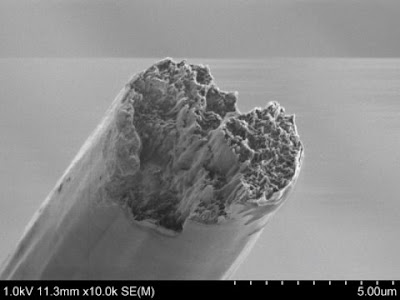

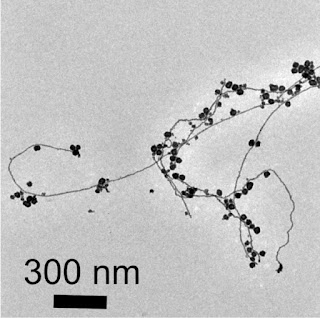

The ultrastrong material is made of cellulose nanofibres (CNF), the fundamental building squares of wood and other vegetation. Utilizing a novel creation strategy, the analysts have effectively exchanged the exceptional mechanical properties of these nanofibres to a naturally visible, lightweight material that could be utilized as an eco-accommodating option for plastic in planes, autos, furniture and different items. "Our new material even has potential for biomedicine since cellulose isn't dismissed by your body," clarifies Söderberg. The researchers began with economically accessible cellulose nanofibres that are only 2 to 5 nanometres in distance across and up to 700 nanometres in length. A nanometre (nm) is a millionth of a millimeter. The nanofibres were suspended in water and encouraged into a little channel, only one millimeter wide and processed in steel. Through two sets of opposite inflows extra deionized water and water with a low pH-esteem entered the channel from the sides, crushing the surge of nanofibres together and quickening it.

This procedure, called hydrodynamic focussing, adjusted the nanofibres the correct way and also their self-association into an all around stuffed plainly visible string. No paste or some other part is required, the nanofibres amass into a tight string held together by supramolecular powers between the nanofibres, for instance electrostatic and Van der Waals powers. With the splendid X-beams from PETRA III the researchers could take after and upgrade the procedure. "The X-beams enable us to break down the point by point structure of the string as it shapes and in addition the material structure and various leveled arrange in the super solid strands," clarifies co-writer Stephan Roth from DESY, leader of the Micro-and Nanofocus X-beam Scattering Beamline P03 where the strings were spun. "We made strings up to 15 micrometers thick and a few meters long."

Estimations demonstrated an elastic firmness of 86 gigapascals (GPa) for the material and a rigidity of 1.57 GPa. "The bio-based nanocellulose filaments manufactured here are 8 times stiffer and have qualities higher than characteristic dragline creepy crawly silk strands," says Söderberg. "In the event that you are searching for a bio-based material, there is nothing very like it. Furthermore, it is likewise more grounded than steel and some other metal or combination and glass filaments and most other manufactured materials." The fake cellulose strands can be woven into a texture to make materials for different applications. The specialists gauge that the creation expenses of the new material can contend with those of solid manufactured textures. "The new material can on a basic level be utilized to make bio-degradable parts," includes Roth.

The examination depicts another strategy that mirrors nature's capacity to collect cellulose nanofibres into relatively idealize macroscale game plans, as in wood. It opens the path for creating nanofibre material that can be utilized for bigger structures while holding the nanofibres' rigidity and capacity to withstand mechanical load. "We would now be able to change the super execution from the nanoscale to the macroscale," Söderberg underlines. "This revelation is made conceivable by understanding and controlling the key crucial parameters basic for idealize nanostructuring, for example, molecule estimate, connections, arrangement, dissemination, organize development and get together." The procedure can likewise be utilized to control nanoscale gathering of carbon tubes and other nano-sized strands.

Source: Materials provided by Deutsches Elektronen-Synchrotron DESY.

Related Conference:

Comments

Post a Comment