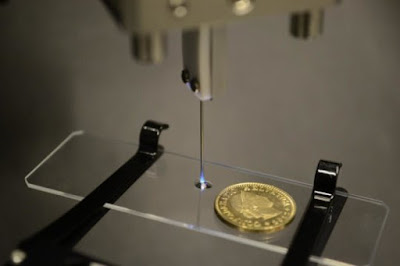

Ultra-thin optical fibers offer new way to 3-D print microstructures

Novel approach lays groundwork for using 3-D printing to repair tissue in the body

Credit: Damien Loterie and Paul Delrot, École Polytechnique Fédérale de Lausanne

https://materialscience-nano.conferenceseries.com/events-list/optical-materials-and-plasmonics

"For the first time, researchers have shown that an optical fiber as thin as a human hair can be used to create microscopic structures with laser-based 3-D printing. The innovative approach might one day be used with an endoscope to fabricate tiny biocompatible structures directly into tissue inside the body"

With encourage improvement our strategy could empower endoscopic microfabrication instruments that would be significant amid surgery," said look into group pioneer Paul Delrot, from École Polytechnique Fédérale de Lausanne, Switzerland. "These instruments could be utilized to print miniaturized scale or nano-scale 3D structures that encourage the attachment and development of cells to make built tissue that reestablishes harmed tissues."

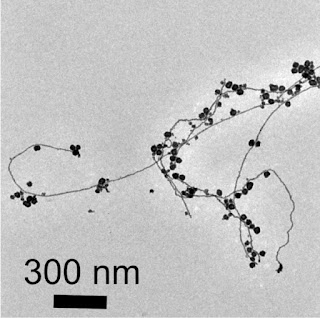

In The Optical Society (OSA) diary Optics Express, the specialists demonstrate that their new approach can make microstructures with a 1.0-micron sidelong (side-to-side) and 21.5-micron hub (profundity) printing determination. Despite the fact that these microstructures were made on a magnifying instrument slide, the approach could be valuable for concentrate how cells connect with different microstructures in creature models, which would help make ready for endoscopic imprinting in individuals.

To make the microstructures, the specialists plunged the finish of an optical fiber into a fluid known as photopolymer that hardens, or cures, when lit up with a particular shade of light. They utilized the optical fiber to convey and carefully center laser light point-by-point into the fluid to construct a three-dimensional microstructure.

By printing sensitive points of interest onto extensive parts, the new ultra-reduced microfabrication device could likewise be a helpful extra to the present monetarily accessible 3D printers that are utilized for everything from quick prototyping to making customized therapeutic gadgets. "By utilizing one printer head with a low determination for the mass parts and our gadget as an auxiliary printer set out toward the fine subtle elements, multi-determination added substance assembling could be accomplished," said Delrot.

Improving the setup

Current laser-construct microfabrication procedures depend in light of a non-straight optical wonder called two-photon photopolymerization to specifically cure a volume somewhere inside a fluid photosensitive material. These procedures are hard to use for biomedical applications since two-photon photopolymerization requires unpredictable and costly lasers that emanate short heartbeats and in addition cumbersome optical frameworks to convey the light.

"Our gathering has ability in controlling and molding light through optical strands, which drove us to surmise that microstructures could be printed with a minimized framework. Also, to make the framework more reasonable, we exploited a photopolymer with a nonlinear measurement reaction. This can work with a basic ceaseless wave laser, so costly beat lasers were not required," said Delrot.

To specifically cure a particular volume of material, the specialists exploited a concoction marvel in which hardening just happens over a specific limit in light power. By playing out a definite investigation of the light examining parameters and the photopolymer's conduct, the analysts found the best parameters for utilizing this compound marvel to print microstructures utilizing a low-control, cheap laser that discharges consistently (as opposed to beat).

To make empty and strong microstructures, the specialists utilized a natural polymer forerunner doped with photoinitiator made of off-the-rack compound segments. They centered a ceaseless wave laser transmitting light at 488-nanometer wavelength - noticeable wavelength light that is possibly alright for cells - through an optical fiber sufficiently little to fit in a syringe. Utilizing an approach known as wavefront forming they could center the light inside the photopolymer with the goal that lone a little 3D point was cured. Playing out an alignment venture preceding microfabrication enabled them to carefully center and sweep laser light through the ultra-thin optical fiber without moving the fiber.

"Contrasted with two-photon photopolymerization cutting edge frameworks, our gadget has a coarser printing determination, nonetheless, it is possibly adequate to think about cell collaborations and does not require massive optical frameworks nor costly beat lasers," said Delrot. "Since our approach doesn't require complex optical parts, it could be adjusted to use with current endoscopic frameworks."

Pushing toward clinical utilize

The scientists are attempting to create biocompatible photopolymers and a minimized photopolymer conveyance framework, which are important before the procedure could be utilized as a part of individuals. A speedier examining speed is likewise required, yet in situations where the instrument measure isn't basic, this confinement could be overwhelmed by utilizing a business endoscope rather than the ultra-thin fiber. At last, a system to finish and post-process the printed structure inside the body is required to make microstructures with biomedical capacities.

"Our work demonstrates that 3D microfabrication can be accomplished with strategies other than centering a powerful femtosecond beat laser," said Delrot. "Utilizing less mind boggling lasers or light sources will make added substance fabricating more open and make new chances of utilizations, for example, the one we illustrated."

Comments

Post a Comment